We have had many enquiries from ISVs regarding the possibility of using AoA in the cloud. The idea is to use a location engine instance to allow their multiple customers to access AoA direction finding as a service.

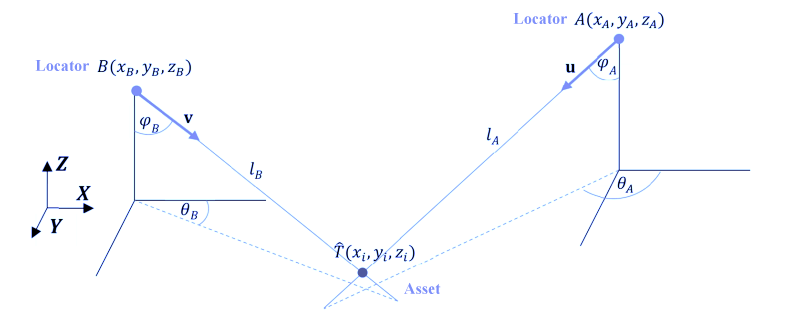

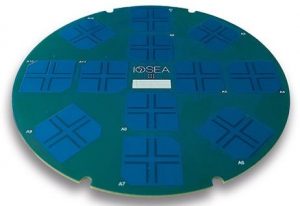

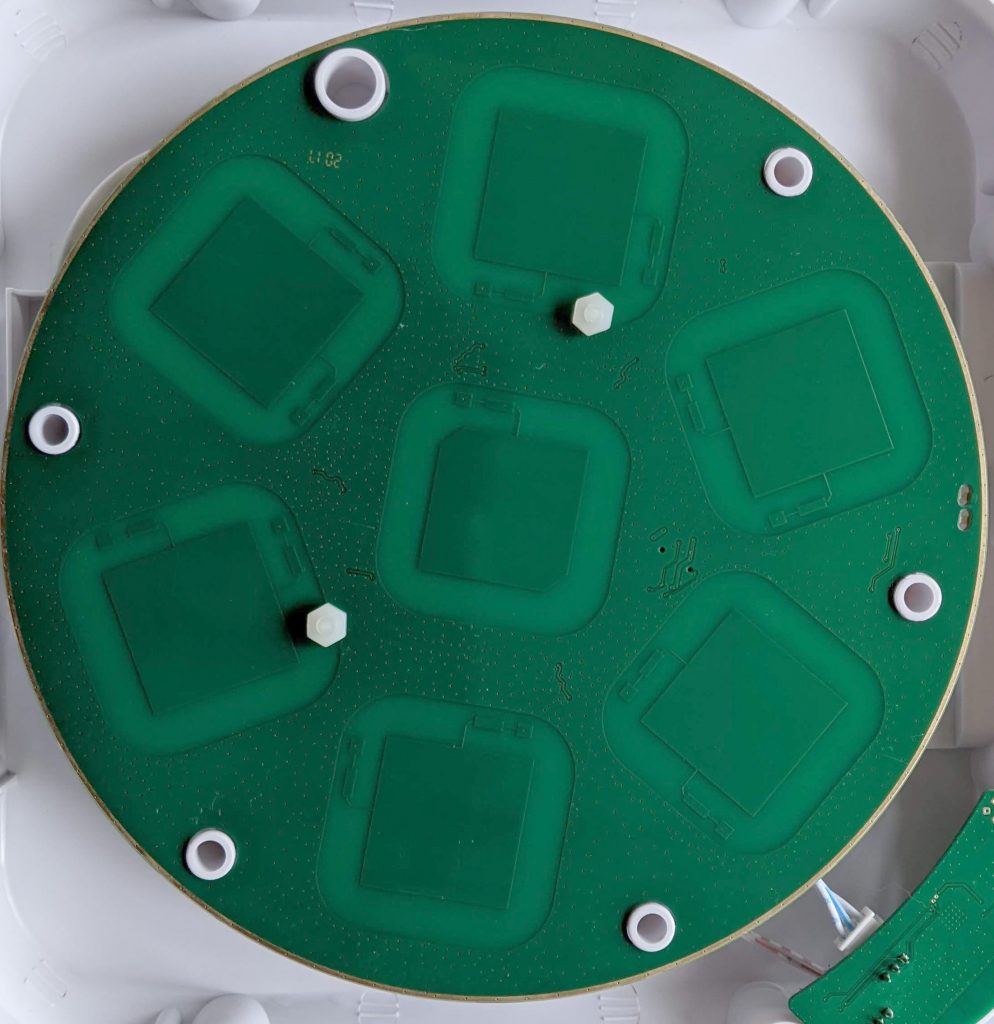

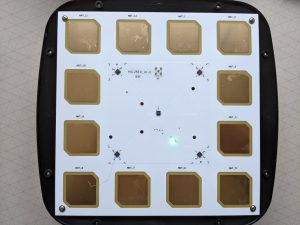

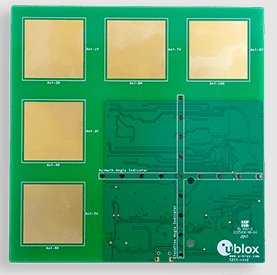

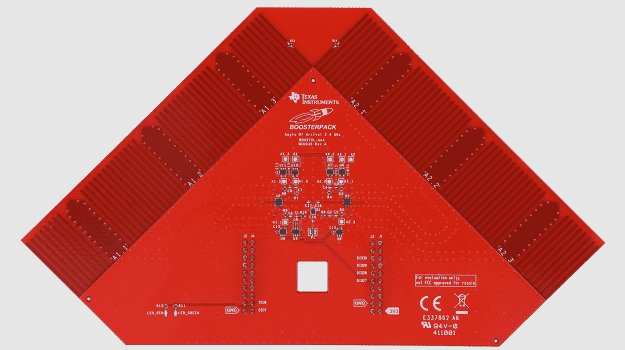

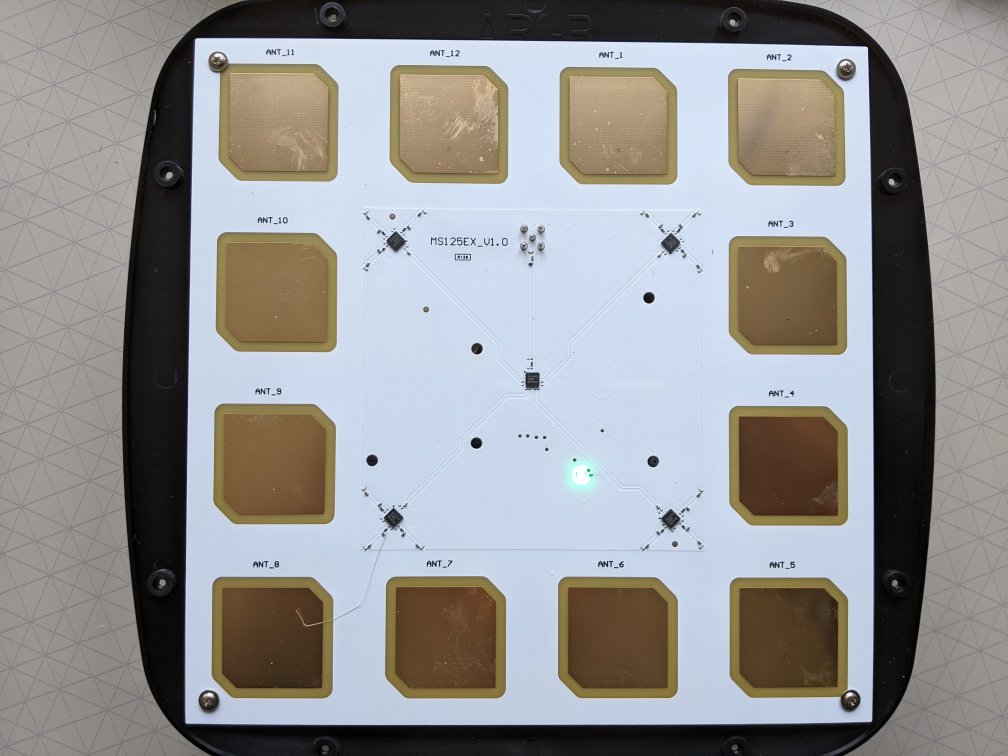

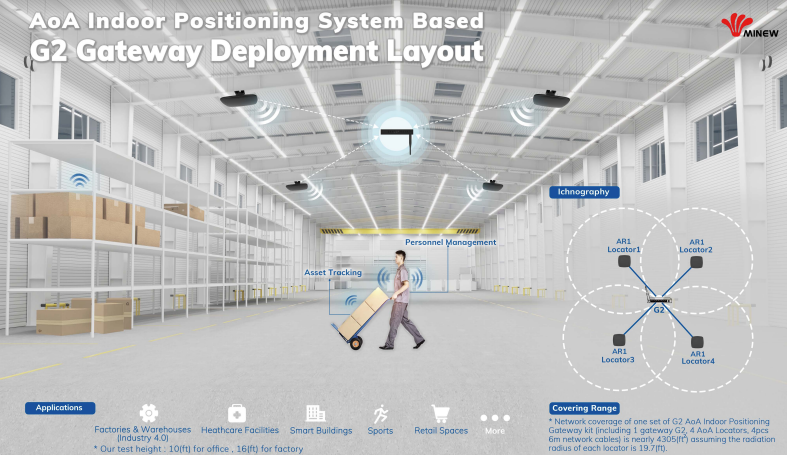

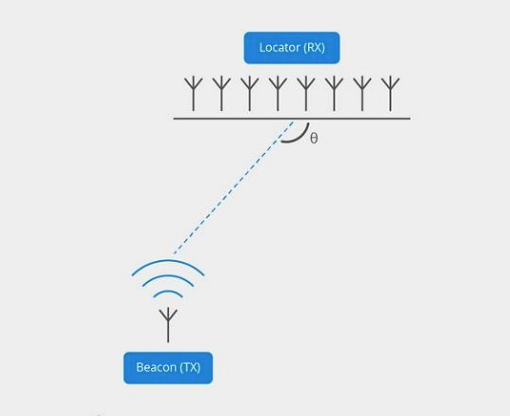

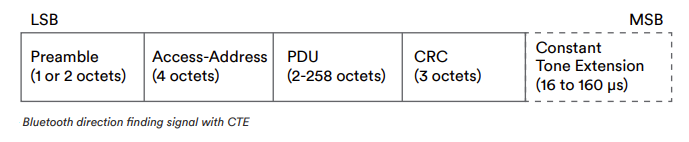

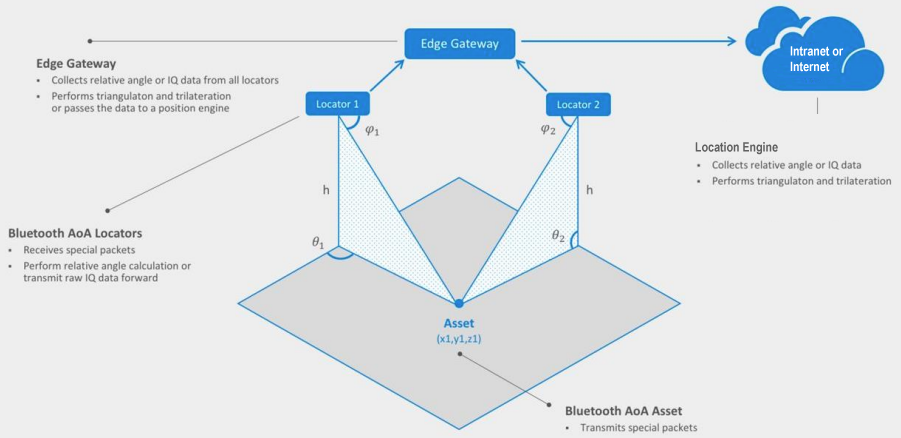

Bluetooth AoA Direction finding works by having multiple locators that communicate with an on-site gateway that connects to the location engine. This is radio data so there’s lots of information sent very often. For large sites, there are multiple edge gateways. In most systems with more than a few assets, the gateway throughput becomes limited by the gateway hardware and the location engine processing input is limited mainly by the CPU capability.

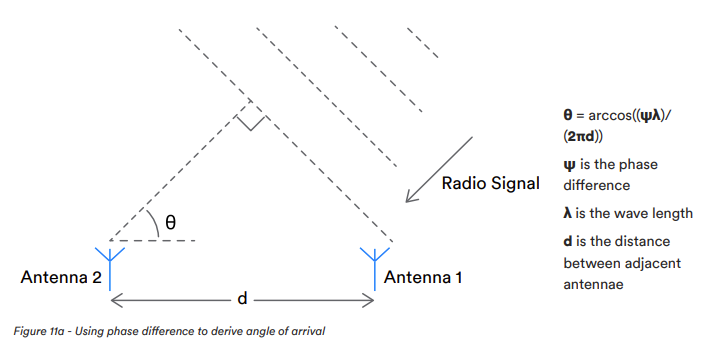

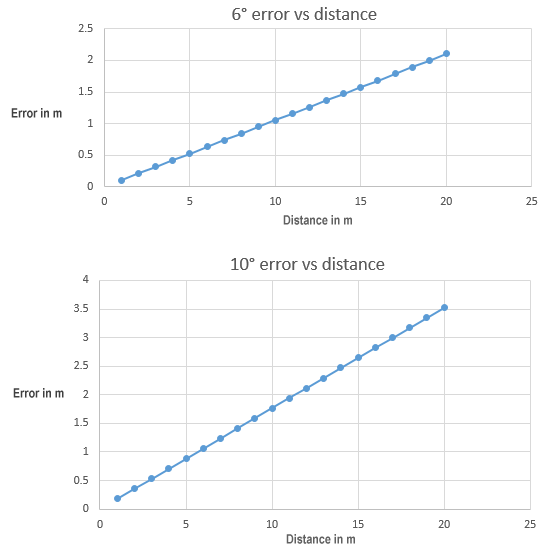

The location engine has to do a lot of work. It implements computationally intensive radiogoniometry and anti-interference algorithms using data from multiple gateways.

In most cases, with large numbers of assets, the gateways and location engine are working near full capacity with the latency of the whole system being balanced against the number of assets.

While such a system can work in the cloud, the bandwidth and latency of the connection to the cloud means that it usually isn’t technically and financially viable. Sharing such a system across customers is even less viable. Instead, standalone systems have to be set up on-site to provide optimum performance.

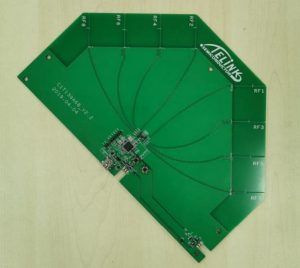

Be aware that some ‘toy’ evaluation, as opposed to production, AoA systems perform the radiogoniometry and anti-interference algorithms at the gateway. While might work for a few assets, the gateway usually doesn’t have the processing power to scale to a production environment. Also, the gateway is only processing the radiogoniometry and anti-interference algorithms using data it has seen. Production grade radiogoniometry and anti-interference algorithms need to consider data from multiple gateways.

Read about PrecisionRTLS™