Recent research A Comprehensive Study on the Internet of Things (IoT) and Micro-Energy Harvesting from Ambient Sources, from researchers in Spain, discusses the potential of micro-energy harvesting (MEH) as a sustainable power source for Internet of Things (IoT) devices, specifically Bluetooth sensors.

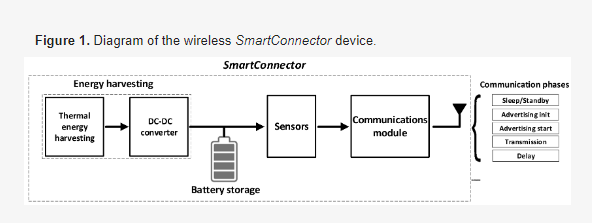

Micro-Energy Harvesting (MEH) is a technology that captures and converts small amounts of environmental energy such as like light, heat, or motion into electrical energy, which can power small electronic devices. The study suggests that MEH could be a sustainable solution for powering Internet of Things (IoT) devices, including Bluetooth sensors, due to their low power requirements.

The benefits of MEH include reducing the need for costly and environmentally harmful battery replacements and enabling the deployment of IoT devices in remote or hard-to-reach areas. The study also points out challenges, such as the small and variable amount of energy that can be harvested, which may not provide a reliable power supply for devices that need a steady source of energy. However, even with small temperature gradients between the environment and the cold side of the thermoelectric generator, it wass possible to make several communications per hour.