Bluetooth technology is playing a transformative role in the Industrial Internet of Things (IIoT), facilitating the digitisation and networking of manufacturing operations to address economic, supply chain and regulatory challenges. This wireless technology enables comprehensive data collection, monitoring, and analysis across interconnected devices, which are critical to the automation and efficiency goals of Industry 4.0.

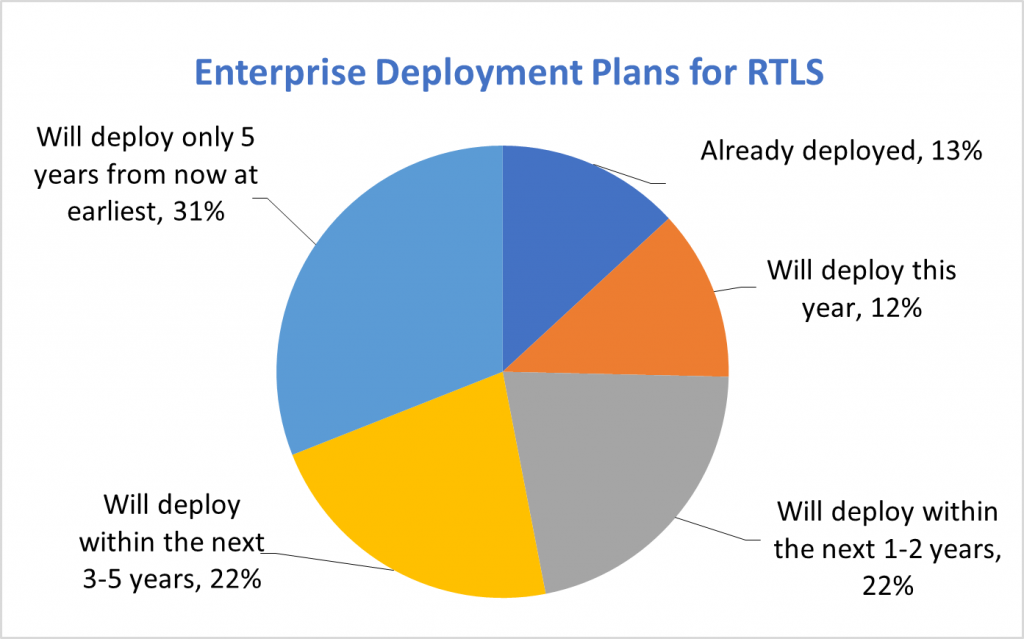

Bluetooth Low Energy (LE) technology has growing importance in industrial settings. According to the 2023 Wireless Connectivity Market Analysis by Techno Systems Research and ABI Research, the market for Bluetooth-enabled industrial devices is projected to grow significantly, from 143 million annual unit shipments in 2023 to over 611 million by 2028, with a compound annual growth rate (CAGR) of 34%. Real-time location systems (RTLS) and asset tracking represent the largest market opportunity due to the availability of low-cost Bluetooth LE tags offering high-accuracy location services.

The second-largest growth area is commercial building automation, which is forecast to expand rapidly, from 8.5 million unit shipments in 2022 to over 135 million by 2028. Other notable markets include Bluetooth LE condition monitoring and predictive maintenance, expected to reach 7 million and nearly 10 million annual unit shipments respectively by 2028.

Robotics is another significant area of opportunity, where Bluetooth LE is enabling autonomous navigation and robot-to-robot communication. Mobile robots, in particular, stand out as they can relay crucial operational data such as position, load, and battery levels, while also allowing for dynamic updates to tasks and routes via Bluetooth-connected devices.

Key advantages of Bluetooth technology in industrial applications include its low power consumption, resilience to interference, robustness, and integration with existing mobile, computing, and IoT infrastructure. Its ability to provide real-time insights into factory operations through extensive data collection, combined with advanced wireless System-on-Chip (SoC) technologies, facilitates improved decision-making and operational adaptability.

This technological advancement extends beyond operations, linking the design and manufacturing processes. By connecting tools like CAD directly to machine tools, Bluetooth enables seamless communication to streamline production, reduce bottlenecks, and enhance product design for simpler manufacturing. These capabilities yield higher productivity, reduced product failures, cost savings, and environmental benefits, revolutionising not only how products are made but also how factories are managed and adapted.