Industry 4.0, or the Fourth Industrial Revolution, is the integration of digital technologies into the manufacturing process to create smart factories. These technologies include sensing, artificial intelligence, machine learning, the Internet of Things (IoT), big data, cloud computing to create more efficient, flexible and customisable manufacturing processes.

A new study by Institute of Technology and Business in České Budějovice, Czech Republic on Possibilities of Using Bluetooth Low Energy Beacon Technology to Locate Objects Internally: A Case Study describes and tests a system capable of locating objects inside buildings using Bluetooth Low Energy (BLE) beacons. The authors conducted a survey of available devices and proposed a low-cost combination of system elements, configured the system, programmed reading gates and web applications for data flow monitoring and finally tested the system in an industrial setting at a manufacturing company in Czechia.

The testing included scenarios with beacon-equipped metal crates being moved around in three different sections of the industrial hall. The study evaluated the system’s ability to detect the beacons and determine their location.

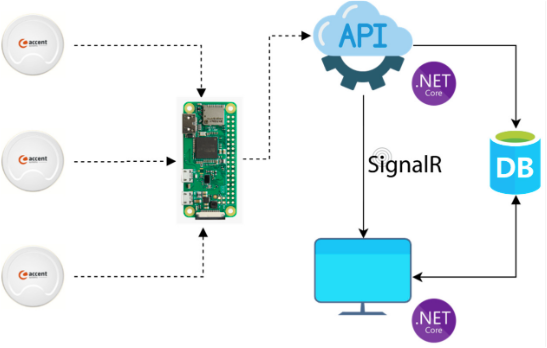

System architecture

The results showed that in the case of direct visibility, the system was able to determine the distance with an accuracy of 94%. However, the measurements also showed that the signal strength was affected by shielding, resulting in worse measurement results in this case and only able to determine the exact distance only 22% of the time.

Crate with a beacon

During a load test, the system and all its sub-components were subjected to several hours of operation, during which the gateways sent requests and collected data about available beacons, processed the requests and stored them in the database. The web application allowed for real-time monitoring of data flow from the individual gateways and the number of beacons in the individual sections. No problems occurred during testing that would cause the measurements to be interrupted, demonstrating the functionality of all system components. The system was considered adequate for most use cases.