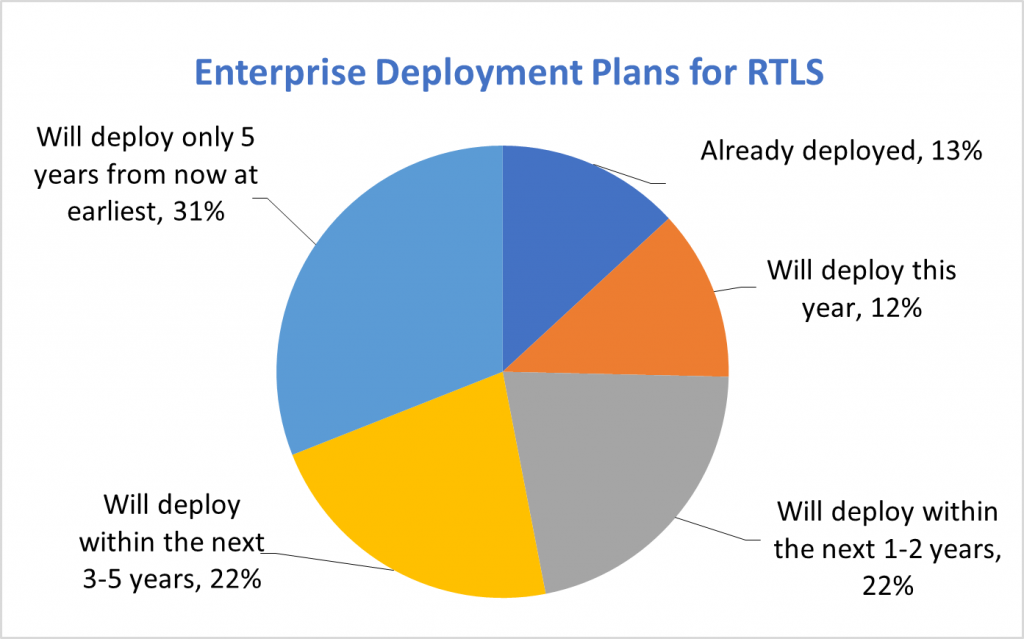

In a previous post on iBeacon Microlocation Accuracy we explained how assets can be tracked using Bluetooth Received Signal Strength (RSSI) or Angle of Arrival (AoA). We advised working out what accuracy is needed prior to seeking out an appropriate solution. However, accuracy isn’t always the only consideration and here is a more complete list of factors.

Accuracy

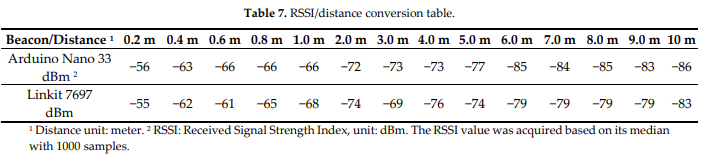

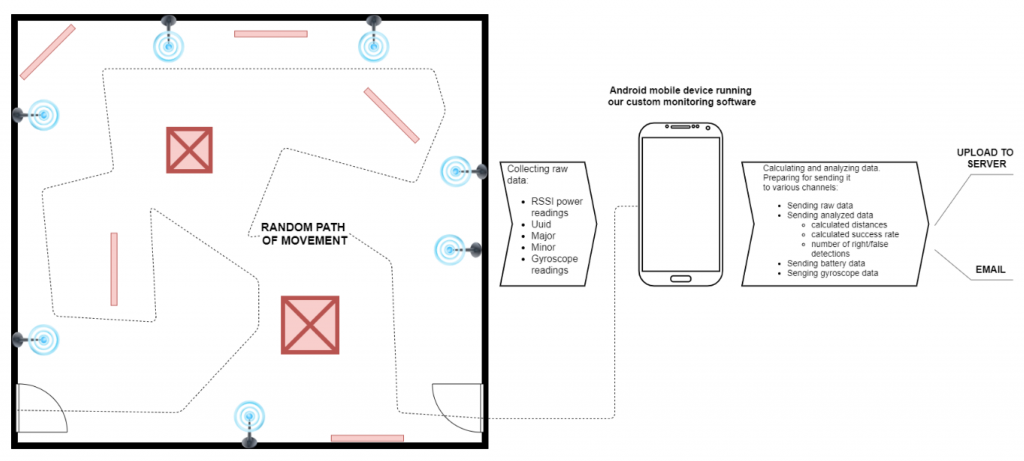

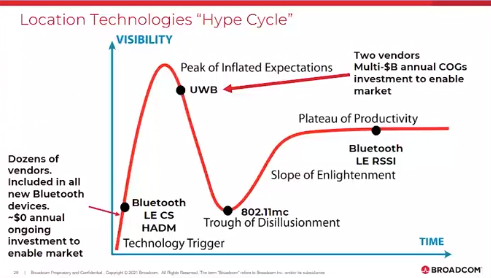

RSSI asset tracking can achieve accuracies of about 1.5m within a shorter range confined space and 5m at the longer distances. RSSI zone-based systems where beacons are found to the nearest gateway, are accurate to the inter-gateway distance that can be of the order of cm. However having such as large gateway density is usually only practical for very small areas.

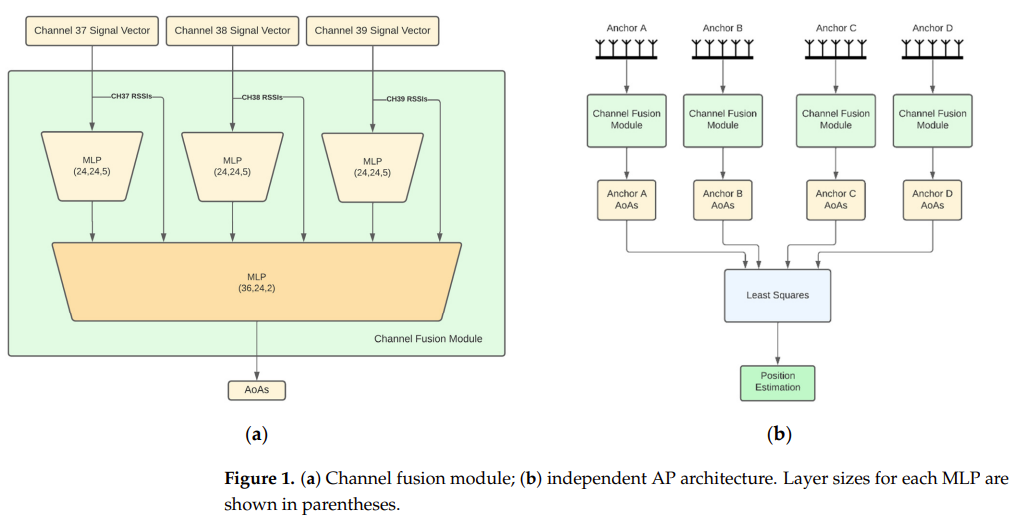

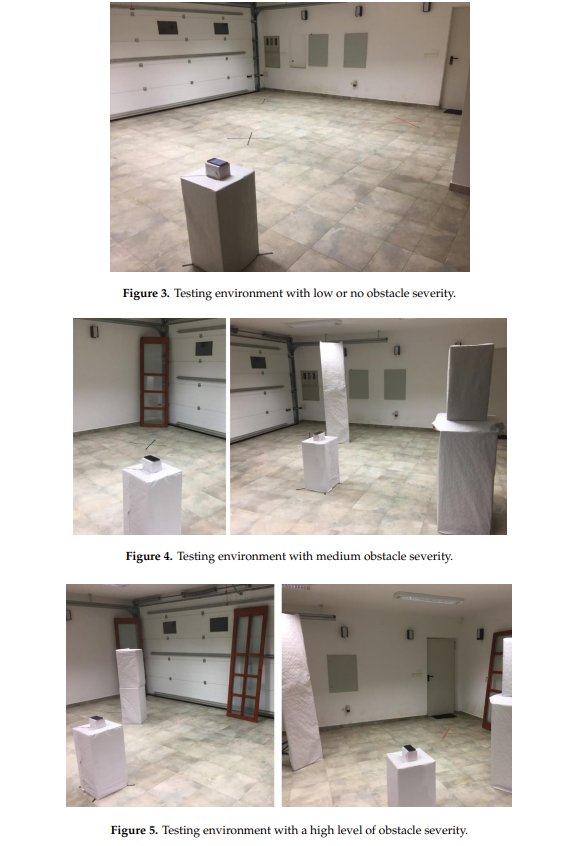

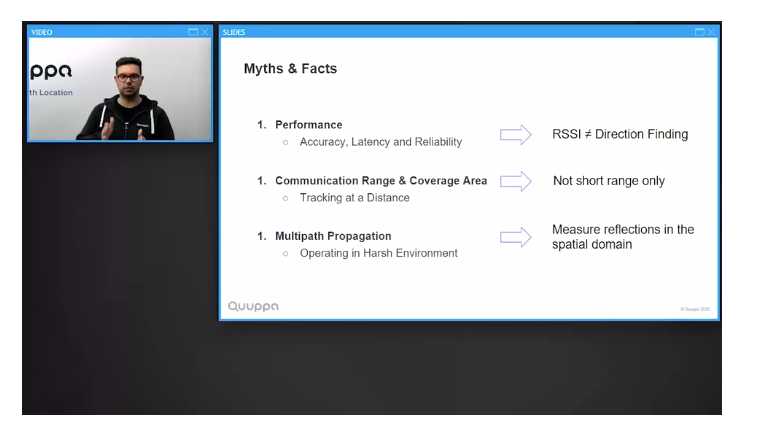

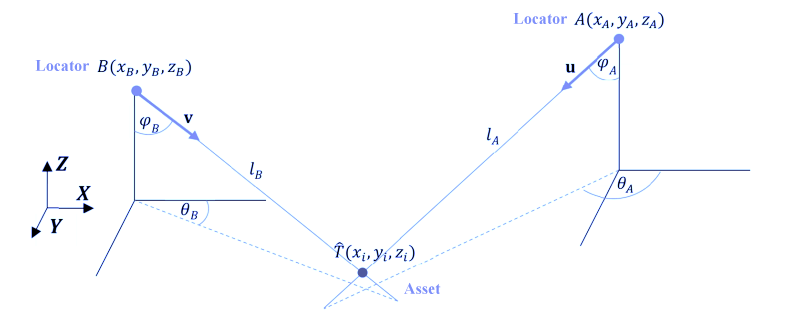

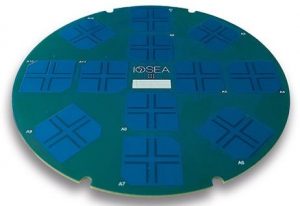

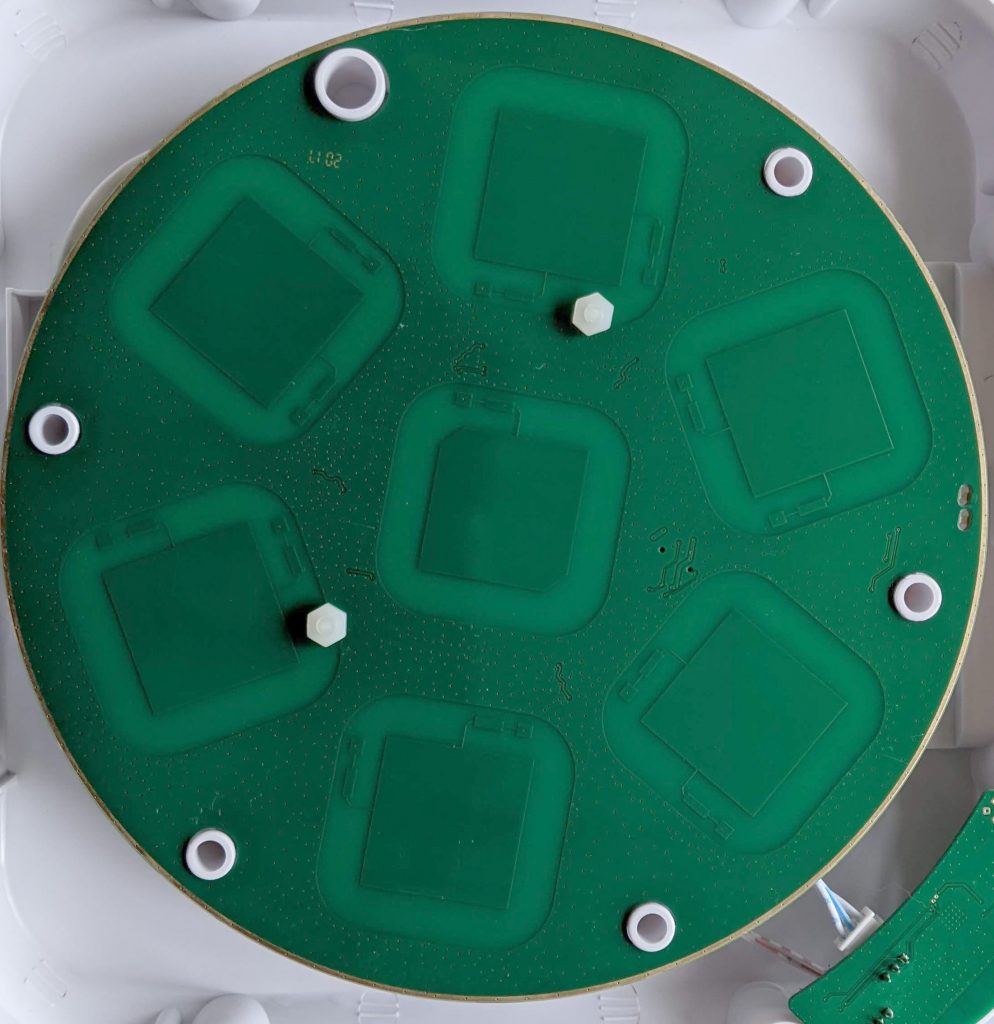

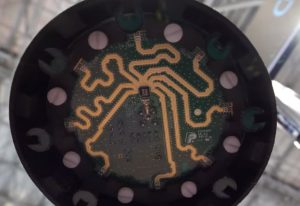

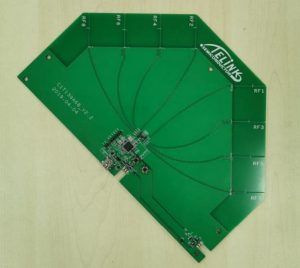

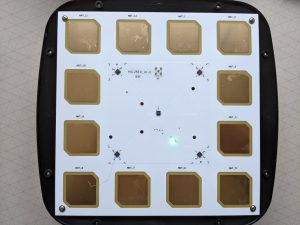

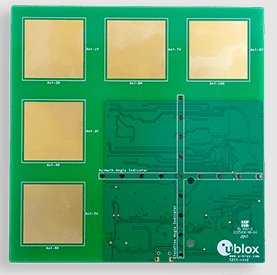

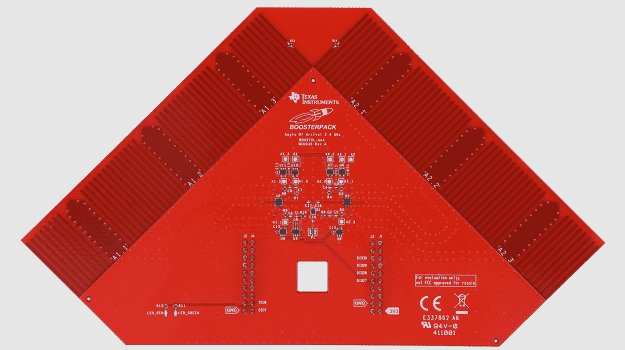

AoA asset tracking achieves sub-metre accuracy. The accuracy depends most on the distance between the locator and beacon but is also affected by the locator hardware quality, radio signal noise, surfaces causing radio reflections, the accuracy of locator placement and beacon orientation.

Maximum number of beacons

AoA-based asset tracking produces and requires much more data which means the locators and software systems have to deal with more data. The data throughput for both types of system depends on the required minimum latency that in-turn depends on how often the beacons advertise. RSSI-based systems support up to high tens of thousands of beacons while AoA supports thousands of beacons.

Beacon variety and IoT

RSSI-based systems can use any beacon and hence support a large range of sensor beacons that can detect movement (accelerometer), movement (started/stopped moving), button press, temperature, humidity, air pressure, light level, open/closed (magnetic hall effect), proximity (PIR), proximity (cm range), fall detection, smoke, natural gas and water leak.

AoA beacons are more specialised and currently only support limited IoT sensing such as movement (accelerometer) and button press.

Cost

AoA locators, gateways and beacons are more complex and are therefore more costly. AoA also needs more locators/gateways per sq area. Hence, AoA systems are x3 to x4 more expensive than RSSI systems.

Setup effort

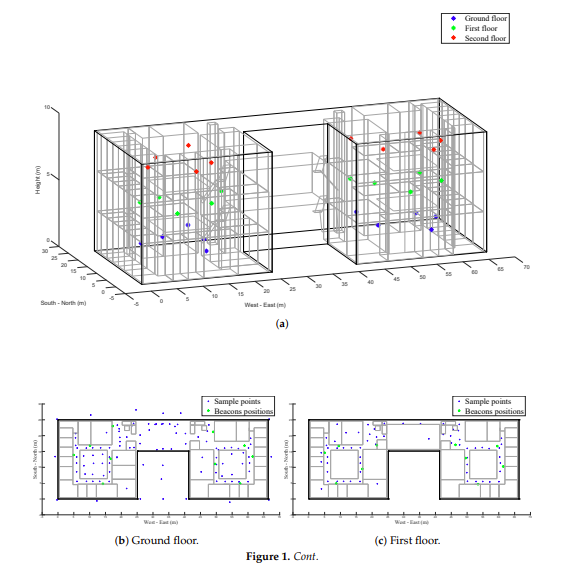

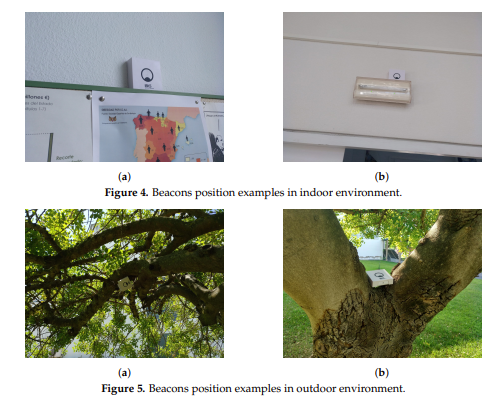

The accuracy of AoA requires that locators be more carefully positioned than for RSSI, in particular the site and AoA locator positions need to be carefully measured.

Beaconzone supplies both RSSI and AoA systems. Contact us to determine the best type of system for your needs.