Recent research looks into a new method for linking industrial assets, like power tools, with their operators using low-power Internet of Things (IoT) devices based on Bluetooth Low Energy (BLE). Despite the wide adoption of asset-tracking technologies, there’s still no widely used solution for dynamically identifying which worker is using which tool. This is important for improving safety, maintenance, and asset utilisation, especially in complex and fast-paced environments like construction sites.

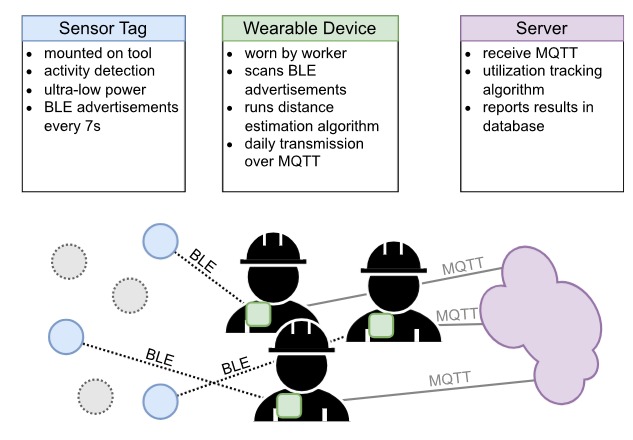

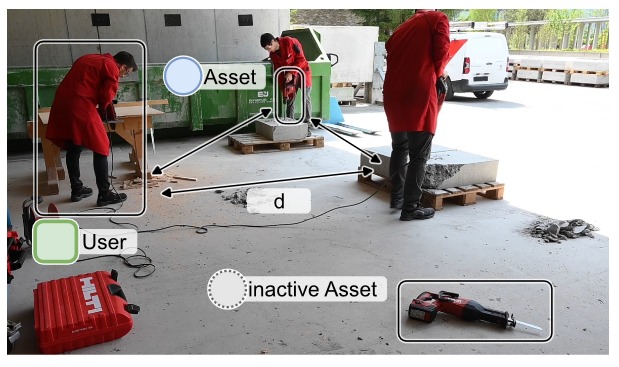

The proposed system includes wearable devices for workers and beacons tags attached to tools. These beacons broadcast data about their usage status, which is picked up by the wearables. The system uses signal strength (RSSI) to estimate the proximity between workers and tools. Since RSSI data is noisy and imprecise, an Extended Kalman Filter (EKF) is employed to improve distance estimation accuracy. A cloud-based algorithm then analyses this data to identify the most probable asset-user matches.

The researchers implemented and tested this system using prototypes in both indoor and outdoor construction settings. The system achieved a median distance estimation error of 0.49 metres and up to 98.6% accuracy in matching tools to their users. The devices were optimised for low energy consumption: wearable devices could run for nearly a month on a single charge, and tags could last for years on small batteries.

The study concludes that the proposed system is a viable and scalable solution for enhancing digitalisation in industrial environments, particularly construction.